Types of Cold Working Processes: Definitions, Applications, and Benefits

Whether you’re sourcing an alloy product for an industrial, medical, or consumer application, there’s a good chance that specific shapes and mechanical properties are required.

That’s where cold work comes in. Cold work is any metalworking process that plastically deforms the alloy below its recrystallization temperature. Each alloy has a unique recrystallization temperature but for the purposes of this article, it’s often found around halfway to the metal’s melting point.

From roll forming and coining to stamping, the result of a successful cold working project is a material with a high degree of dimensional and mechanical precision, as well as excellent reproducibility and interchangeability.

Many metals become harder when deformed due to activity at the atomic level. Work hardening occurs when metal is put under stress and atoms in its grains dislodge and “lock” into place. When this happens over and over again, the metal becomes more resistant to further deformation because many of its atoms have locked into place. Thus, the addition of work, or energy, makes the metal stronger.

Sometimes, work hardening is accidental and unwanted. However, it is often the result of intentional activity because strong materials are desirable in many contexts.

As a result, cold working processes are common in aerospace and automobile manufacturing and several other industries.

Hot Work versus Cold Work

As their names suggest, the main difference between hot and cold work is temperature. However, there are a number of other important ways in which these two metal forming processes are distinct.

Recrystallization and the Metal Forming Process

Recrystallization is an important phenomenon in metallurgy. It occurs when metal atoms are energized to a point at which new crystals start to form. Just like water changes phases to steam and ice, metal has its own phase changes. Every metal has a unique recrystallization point.

The technical definitions of both hot and cold work refer to the recrystallization temperature of the metal. Hot working occurs when metal is deformed above its recrystallization temperature. In contrast, cold working occurs when metal is deformed below the recrystallization temperature. A third metal forming process, warm forming, sits between the two.

When to Use Hot versus Cold Work

Hot work has different requirements and results than cold work does. These differences are essential to keep in mind when you choose a metal-forming process. For example, stainless steel that has undergone hot working will have no strain hardening, high ductility, and an absence of residual stress. However, hot working requires a large amount of heat energy, which entails a short lifespan for metallurgical tools and equipment, indirectly raising costs.

A cold working process does not require any heating, but this comes at its own cost. To cold work stainless steel, one must bring higher forces to bear in order to deform the metal. This tradeoff results in smoother metal surfaces and greater control over mechanical properties.

Types of Cold Working Processes

As with heat treating, each of the dozens of types of cold working processes has its own particular benefits and drawbacks. Manufacturers choose between the different options by assessing the use that the metal will be put to.

Methods and Examples of Cold Working Metal

The variety of processes reflects the variety of use cases for metal. Each method of cold working produces metals with distinct characteristics.

There are four main types of cold working processes:

- Squeezing

- Bending

- Shearing

- Drawing

Precision stamping is a complex process that includes several of these coldworking methods.

Squeezing

Rolling, cold forging, coining, and extrusions are all coldworking methods that can be thought of as squeezing.

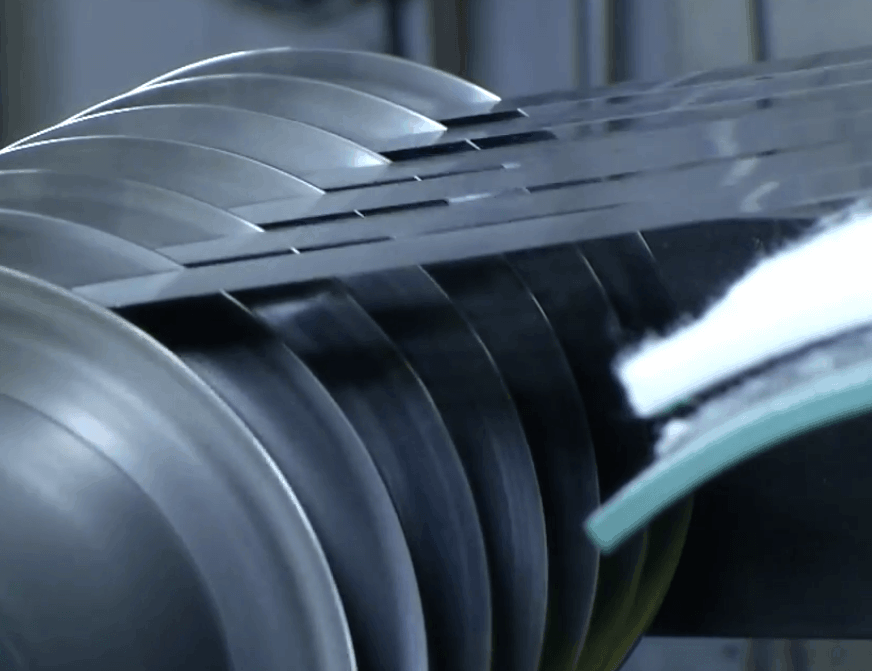

Cold rolling, one of Ulbrich’s key capabilities, is by far the most common cold working method. Sheet, strip, and more can be cold rolled to create products with smooth surfaces and specific material properties.

Cold-rolled steel is put under severe stress. Its resulting strength is due to strain hardening, which can render the metal up to 20 percent harder than it was before.

In cold forging, metal is placed between two dies, and the dies are then pounded. As a result, the metal takes on the shape of the dies.

In extrusion, the metal is forced through a die, which works it into a given cross-section.

Bending

These methods are primarily used to give alloy products shape.

Roll forming involves bending a long strip of metal (usually coiled steel) passed through sets of rolls, each performing an incremental part of the bend. The finished product is bent until the desired cross-section profile is reached.

Tube, roll, and angle bending are other common methods used.

Shearing

Slitting sheet into strips is perhaps the most common shearing method of cold working.

Steel slitting is a process that cuts a wide master coil of metal into narrower strands that have more consistent measurements. Manufacturers simply feed the large stainless steel through a machine called a slitter, then recoil the resulting strands into a finished coil. However, the machine’s knives leave behind a burr on the slit edge.

Drawing

Cold drawing sees metalworkers draw, or pull, metal. This extends the material without cracking it.

When deep drawing metal, a rolled coil is punched through a hole or die. The punch is used to achieve the desired shape. The die cavity matches the punch but is slightly wider, which allows for passage and clearance. The raw material is forced into the die via the compression force. Each draw operation is a separate step, and with each step, there is a reduction in diameter, increasing the height or depth of the part. This is done to ensure that, as the metal changes shape, re-crystallization occurs as well. Products made by deep drawing include battery enclosures, implantable medical devices, aerospace, and defense components for aircraft.

Precision Stamping

Metal stamping is another manufacturing process ideal for producing metal products where tight tolerances are required. In metal stamping, a flat metal strip coil is converted into various shapes. This complex process includes a few different metal forming techniques, like punching, coining, piercing, blanking, and bending, among others.

Applications and Benefits of Cold Working

There are a number of different benefits associated with cold work. These ensure that demand for cold working processes remains high, even though they require a great deal of force.

Applications of Cold Working

Cold work has many applications. These include the following:

- Vehicles such as aircraft, automobiles, and ships have many cold-worked components

- Medical devices and applications, such as pacemaker stamping and hypodermic needle manufacturing.

- Blind rivets, gaskets, and shielding.

- And many other complex shapes can be best made through cold working

Benefits of Cold Working

Cold working is a dependable way to make metals stronger. In fact, much hot-rolled steel is subsequently cold rolled to give it desirable mechanical properties, such as increased tensile strength. Together, hot rolling and cold rolling are the most utilized metallurgical processes.

In addition to increasing the strength of metal, cold rolling also makes surfaces smoother. In terms of the roughness height (a measure of surface irregularities), cold-rolled steel can be ten times smoother than hot-rolled. This makes cold working a leading choice for producing the metal surfaces found in consumer goods.

Moreover, because cold working does not produce metal waste, often called scrap metal, it is an economically efficient option. While hot working involves soaking pits and furnaces, they are not needed in cold working.

Materials That Can and Cannot Be Cold Worked

As with many industrial processes, cold working is only suitable for a select range of metals. In addition to being limited to certain types of metals, it is also limited to certain sizes of metal. Other kinds and sizes are better suited for hot forging.

Materials That Can Be Cold Worked

Cold work can be done on a wide variety of metals. These include tool steels such as stainless steel, nickel-based alloys, some titanium grades, cobalt, copper, and aluminum alloys.

Materials That Can’t Be Cold Worked

Cold working is only suitable for smaller-sized pieces of metal because the force required to cold work a larger metal would be enormous. Typically, cold working cannot be done on anything with a diameter greater than twenty-five millimeters. These larger pieces may have to be hardened using another method.

Additionally, some types of metals simply cannot be cold worked. These include carbon steel, alloy steels that are not ductile at room temperature, and titanium grade 5. Moreover, some metals that can be cold worked, like copper, can become brittle after cold working.

Learn More about Cold Working Processes

Due to the variety of cold working methods, it’s important to choose the optimal process for your unique use case. The right kind of cold work can result in a metal that is stronger, smoother, and more effective. For more information about the cold work processes offered by Ulbrich, contact us today.