Special Metal Spotlight: A286 Stainless Steel

You might be confused by this article’s title. Is A286 a stainless steel or a special metal?

The answer, of course, is yes.

A286 stainless steel holds a unique place in material science as it serves dual roles: it’s classified as both a stainless steel and a special metal. As an iron-based alloy, it fits within the stainless-steel family due to its high corrosion resistance and austenitic properties. At the same time, it is considered a special metal for its exceptional high-temperature performance, strength, and mechanical properties that surpass those of conventional stainless steels. This dual identity makes A286 stainless steel a standout choice for applications that demand durability and versatility.

Whether you’re designing components for jet engines, manufacturing fasteners that must withstand cryogenic temperatures, or producing parts for demanding industrial environments, choosing the right material can be daunting. A286 stainless steel offers a solution, delivering unmatched reliability and performance.

At Ulbrich, we work with you to customize your A286 alloy materials to meet the unique demands of your project. With decades of experience in precision manufacturing, we’re here to simplify the process and help you achieve your goals.

A286 Stainless Steel in Action: Applications and Advantages

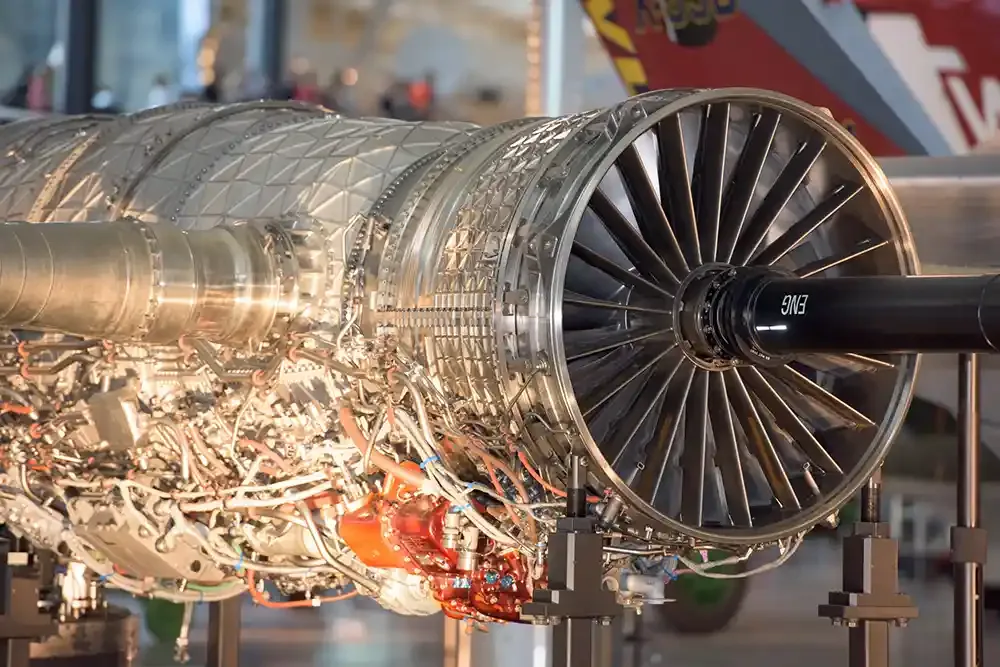

Imagine the critical role materials play in aerospace engineering. Turbine blades in jet engines must endure temperatures over 1300 °F while maintaining structural integrity. Fasteners in these same engines must hold tight in extreme conditions, resisting both corrosion and fatigue. In low-temperature environments, such as cryogenic storage systems, materials must remain strong and ductile to ensure safety and reliability. For these scenarios and more, A286 stainless steel emerges as a trusted ally.

Its unique properties—a combination of high strength, excellent corrosion resistance, and temperature resilience—make A286 stainless steel indispensable for manufacturers tackling these challenges. When coupled with Ulbrich’s precision processing, this alloy becomes even more powerful. Our ability to cold roll, heat treat, and finish A286 to exacting standards ensures the material performs seamlessly in your application.

Here are just a few of the ways A286 stainless steel is used:

- Aerospace: Jet engine components, turbine blades, and high-performance fasteners.

- Energy: Cryogenic storage tanks and heat exchanger systems.

- Industrial Manufacturing: Corrosion-resistant fasteners and components for chemical processing.

Why A286 Stainless Steel is the Right Choice

Selecting a material for demanding applications involves balancing performance, reliability, and cost-effectiveness. A286 stainless steel stands out because it can be precisely tailored to meet specific requirements. For example, its high-temperature resistance up to 1300 °F makes it ideal for jet engines, while its exceptional low-temperature performance ensures reliability down to -320 °F. Unlike other materials, A286’s ability to be precipitation hardened allows for uniformity and consistency across components.

Ulbrich takes these advantages even further by delivering A286 in strip and shaped wire product forms with unparalleled precision. By working closely with our customers, we address their unique needs, whether it’s achieving exact thickness tolerances, enhancing strength through work hardening, or delivering an exceptional surface finish. Our expertise means you can count on reliable performance, reduced waste, and materials that are ready to meet the demands of your production line.

Tailoring A286 to Your Needs

At Ulbrich, we recognize that no two projects are the same. That’s why we focus on customizing A286 stainless steel to align with your specific application. For customers in the aerospace industry, we ensure that the material meets stringent standards like AMS 5525 and AMS 5858, delivering the high-strength, corrosion-resistant properties required for critical components. For manufacturers tackling cryogenic applications, we emphasize ductility and reliability at extreme low temperatures.

This approach reflects our commitment to act as a true partner dedicated to ensuring your success. Our advanced processing capabilities include precision rolling and slitting, enabling us to provide A286 stainless steel that integrates seamlessly into your manufacturing processes. By working with Ulbrich, you gain access to expertise that ensures your material performs exactly as needed, every time.

A286 Stainless Steel in Comparison

Choosing between materials for high-performance applications can be challenging. Let’s explore how A286 stainless steel compares to other commonly used alloys:

- A286 vs. 17-4 PH Stainless Steel: While 17-4 PH offers higher tensile strength, it lacks the high-temperature resilience of A286. For jet engines or other environments requiring sustained performance at 1300 °F, A286 is the superior choice.

- A286 vs. Inconel 718: Inconel 718 is known for its exceptional performance in ultra-high-temperature environments. However, A286 provides a cost-effective alternative for applications requiring high strength and moderate temperature resistance, along with better formability.

- A286 vs. 316 Stainless Steel: While 316 stainless steel is widely used for its corrosion resistance, it cannot match A286’s strength and ductility at cryogenic temperatures, making A286 the clear choice for low-temperature applications.

Through these comparisons, it’s evident that A286 offers a unique balance of properties that makes it a versatile and reliable choice for a wide range of industries. With Ulbrich’s tailored processing, the alloy’s advantages are fully realized, helping you overcome challenges and deliver excellence.

Ulbrich: Your Trusted Partner in A286 Stainless Steel

Collaborating with Ulbrich means more than acquiring material; it’s forming a partnership dedicated to achieving your success. We understand the pressures manufacturers face, from tight production schedules to stringent performance requirements. That’s why we go above and beyond to ensure the materials we deliver exceed expectations.

Ulbrich is able to supply A286 in standard gauges and widths or in more custom configurations with tailored mechanical properties, thicknesses, and surface conditions, as well as custom profiles with our shaped wire product forms.

Our A286 stainless steel strip and wire are meticulously processed to provide:

- Consistent Quality: Eliminate variability and ensure reliability across production runs.

- Custom Mechanical Properties: Tailored strength, ductility, and corrosion resistance to meet your needs.

- Streamlined Integration: Precision rolling and slitting ensure compatibility with your manufacturing processes.

Whether you’re in aerospace, energy, or industrial manufacturing, Ulbrich has the expertise and capabilities to help you succeed. Let us show you how our A286 stainless steel can transform your production process and deliver exceptional results.

Get Started Today

If you’re ready to experience the benefits of precision-engineered A286 stainless steel, we’re here to help.

Contact us today to discuss your application and discover how Ulbrich can provide the solutions you need.