A Guide to Precipitation-Hardening Stainless Steel Alloys

Designers of stainless steel and nickel alloy products are routinely faced with making tradeoffs between the properties needed for manufacturing and those required for its end use. When such compromises begin to adversely impact cost or performance, precipitation hardening stainless steel (PH) alloys may offer a solution. Good candidates are strip and wire components that must be extensively formed or drawn during the manufacturing, then must exhibit high strength and toughness in service.

PH alloys are similar to other stainless steel and nickel-based alloys, with one major exception: They contain small additions of copper, aluminum, phosphorus, or titanium. After a part made of a PH alloy has been formed, it is given an age-hardening treatment in which these elements precipitate as hard intermetallic compounds that significantly increase hardness and strength.

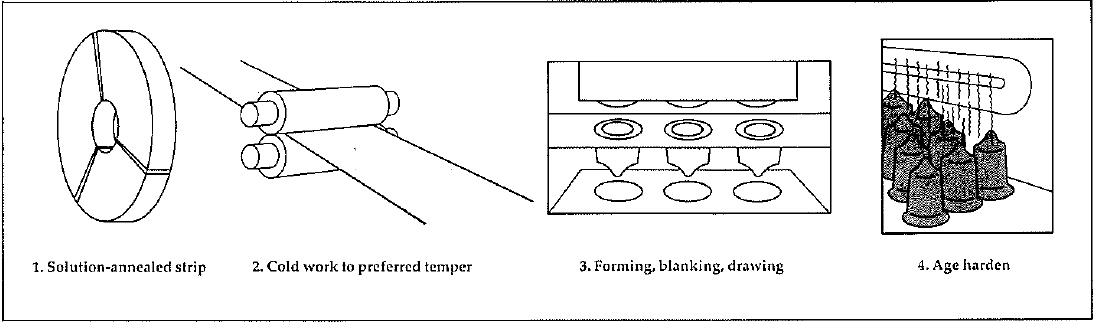

There are four key operations required to produce precipitation-hardenable parts. The precipitation hardening process begins with solution annealed strip (1), which is cold worked at room temperature to the preferred temper (2). The part is then formed, blanked, and drawn (3). The final step (4) is the age hardening of formed parts that have the required strength and hardness.

Despite their more complex metallurgy, PH alloys are not necessarily more costly than many non-age-hardenable alloys. In fact, performance may be substantially higher than such alloys, without a cost penalty. Although corrosion resistance is decreased (or possible increased) during the aging cycle, it is only by a slight amount.

This article takes a closer look at PH stainless steel and nickel alloys and provides several examples of applications.

What’s the Difference Between Annealed and Tempered Precipitation Hardening Stainless Steels?

Precipitation hardening stainless steel alloys are available in one of two conditions – annealed (condition A) or tempered (condition C). The annealed alloys, with Rockwell hardnesses in the broad range of B75 to C20, are relatively soft and formable. After forming, parts can be age-hardened to Rockwell C35 to C49.

Tempered alloys are passed through a rolling mill at room temperature to impart an element of cold work, usually 60%. From this condition, the alloys can be heat treated to exceptionally high hardness levels – Rockwell 50C is not uncommon – and yield strengths in the 1200 to 1790 MPa (175 to 260 ksi) range. Condition C is the starting point for very high strength parts, but forming must be minimal and simple, with generous radii.

Not surprisingly, most users need more options. Condition A may be too soft as a starting point to heat treat the part to the strength required; and condition C may be too hard for forming. In such cases, a precision reroll mill who can fine tune the hardening process may be of service.

Tailoring PH alloys to the task

Rerollers are specialty producers who stock cold-and hot-rolled stainless steel and nickel alloy strip in large quantities. They custom roll it to gauge and temper, heat treating it between passes to neutralize the effects of work hardening. By controlling the amount of cold working, they can achieve an intermediate temper, somewhere between conditions A and C.

Rerollers start by rolling a specific area reduction into the material at room temperature, to achieve a temper that may be the maximum for forming – any harder would be difficult to form or otherwise fabricate. Then they age-harden a sample of the strip or wire according to a cycle recommended by standard specifications, and measurements, rerollers determine the best cold-worked temper for forming and predict the tensile or yield strength that will be produced in the aging cycle.

Heat treatment can be as simple as 90 minutes at 565°C (1050°F), as in the case of Armco’s PH 15-7Mo Stainless Steel. For other alloys, treatment may involve various stages of heating, holding, and cooling, with cycles that might be 16 to 20 hours in duration. Selection of the aging cycle is based to a great extent on whether the alloy is austenitic, martensitic, or semi-austenitic. The end use of the part and the type of heat treatment available governs which of these alloys would be most suitable.

Austenitic PH alloys

The austenitic grades of PH alloys are used in applications that require high strength, moderate corrosion resistance, and good fabricability. The best known is Alloy A286, from Allegheny Ludlum Corp. This is an iron-nickel-chromium alloy with age-hardening elements of aluminum and phosphorus. It has excellent strength and good corrosion resistance in temperatures up to 700°C (1300°F).

Austenitic stainless steel grades require high aging temperatures, about 700°C (1300°F). Their corrosion resistance is decreased slightly by this heat treatment, but oxidation resistance remains very good.

Martensitic PH alloys

The solenoid and large washer seen above are both made of Armco’s 17-7 PH martensitic stainless steel. This grade is typical of very high chromium-content PH alloys, which have excellent oxidation resistance. It can be heat treated at relatively low temperatures, and exhibits high strength and other beneficial mechanical properties in elevated-temperature service.

Martensitic grades also exhibit dimensional stability during age hardening (they contract about 0.0005in./in.), making them ideal for formed parts that must meet tight tolerance specifications. The 17-7 PH washer is used in both aircraft and oil field applications. It has a 63.5 mm (2.5 in.) outside diameter and, although a simple shape, presents some difficulty in forming because of its large open middle. In application, it requires both spring properties and the ability to maintain perfect roundness. After forming, a precipitation-hardening treatment brings its strength up to 1380 MPa (200 ksi).

The solenoid spring is a welded assembly that gets its brownish color from being heat treated for several hours at up to 900°C (1650°F) in an open air furnace. This treatment imparts very specific spring properties without compromising the tiny welds that join the network of spring leaves.

Semi-austenitic PH alloys

Semi-austenitic PH alloys are much more complex metallurgically than the other stainless steels. They are austenitic in the annealed condition and must be transformed into martensite in order to age harden. A typical cycle might consist of heating to very high temperatures, 995°C (1750°F); cooling to -75°C (100°F) to effect the transformation to a martensitic structure; holding for three to eight hours, then precipitation-hardening between 450 and 565°C (840 and 1050°F) for 60 to 90 minutes; followed by air cooling.

The best availability of sheet and strip products will be found in grades PH 15-7 Mo (Armco) and AM-350 (Allegheny Ludlum). Grade 15-7 PH is very similar to the martensitic 17-7 PH alloy, but has a low molybdenum content that provides even higher strength levels in the age hardening process. AM-350 is similar to both 15-7PH and 17-7 PH, but has a slightly better high-temperature capability.

Nickel alloys

Nickel is one of the more desirable alloying elements for applications where high temperature corrosion resistance is required. Among the nickel-chromium alloys, Inco’s Monel K-500 is the choice for many high-strength parts used in demanding environments. It can be age-hardened to yield strengths up to 1030 MPa (150 ksi) and 20% elongation, with ductility increasing as strength levels diminish. Furthermore, it maintains both strength and ductility over a wide range of temperatures, from -250 to 650°C (-425 to 1200°F).

The long blanked strip from the same image above is made of Inco’s Inconel 718. It operates reliably over the same temperature range as Monel K-500. Moreover, Inconel 718 can be welded in the fully aged condition, and it has good oxidation resistance up to an elevated temperature of 970°C (1780°F). Yield strengths are up to 1170 MPa (170 ksi), with 17% elongation.

In application, this part has to remain very rigid in a high-temperature atmosphere, yet must retain enough ductility to accommodate the slight movement of adjoining parts. After the part is blanked, it is given an 18-hour precipitation-hardening cycle to bring its strength up to 1380 MPa (200 ksi).

Other stainless steel families include:

When to ask for the help of an experienced metallurgist or development partner

For all the compositions cited, specific heat treatments are best selected from manufacturers’ data or standard industry specifications such as ASTM or AMS. When heat treating plays a significant role in engineering the part, the services of an outside heat treater experienced with aircraft or corrosion-resistant alloys might be indicated.

Designers who are hesitant about entering “the realm of metallurgy,” will find that using precipitation hardening alloys is not as complicated as it might seem. Producers and distributors of these alloys are well prepared to guide the uninitiated through the many steps between alloy selection and a successful part.

Written By Ron Brucker